VR Crank Sensor Signal Problem – Rev Limit/Misfire

If you have been following us you’ll know that we have been reviewing a DET3+ from ECUMaster and we had major problems with a 1200 rpm “rev limit” and backfire related to a problem with the crank sensor signal.

Looking at various posts (eg here & here) on various forums this crank signal issue seems to be super common so I thought I’d do a quick article detailing the fix that worked (for us).

In the forum posts linked to above, both solutions were to swap the wires on the VR sensor signal. However, we tried that and had no joy, the engine would not even start when we did this.

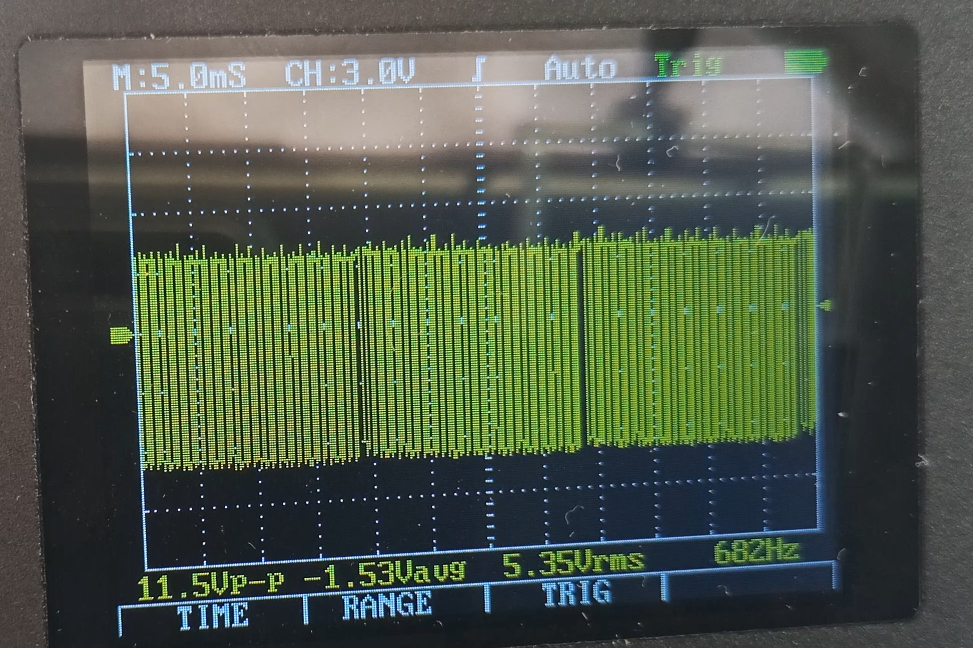

So after buying this oscilliscope (its great!) we got the waveform from the sensor signal.

This helped. In a way.

It confirmed that the signal that we were getting from the VR sensor was not breaking up and was clean, so the problem was not the sensor.

But there was a problem on the output of the DET3+. The output would break up and send random missing tooth signals to the car’s ECU causing the rev limit at 1200rpm and the back fires. But why if the crank sensor signal is good?

After more searching we stumbled upon this excellent documentation from DTA Fast in the UK.

To say it is superior to anything we found from ECUMaster would be an understatement. (This fact alone has made up look seriously at DTA Fast for our next ECU!)

VR Crank Sensor Signal – The Solution

On page 5 of the linked document above it says

If the voltage falls through the gap

Yeah, this is what we get on the crank sensor signal going to the DET3+ piggyback ECU

the engine may start but at a certain RPM will begin to give crank shaft errors and re-synchronisations.

DTA Fast exactly describe the problem we are having ie engine will idle but at a “certain RPM” we will get problems. And they explain exactly what to look for to diagnose the problem, the falling wave.

Again, absolutely excellent documentation.

So now we know the problem, why didn’t swapping the wires coming from the VR sensor solve our problem earlier?

Because we also need to swap the output ignition signals going from the DET3+ ECU going to the engine’s original ECU.

Forums

It’s great being able to check forums for answers. The inverting the signal wires was half the right answer.

The problem was is that there weren’t enough details (at least for us!) to understand the problem and to understand why swapping the VR sensor wires would help.

With the oscilloscope we could see that we were getting the exact waveform DTA highlighted and this told us for sure that we had the wiring on the crank signal inverted.

We now knew that to progress in fixing this problem we had to change the wires regardless of whether the engine started or not.

DTA gave us the foundation to move forward in the troubleshooting process.

Given that we knew that the engine was not going to run with the wires inverted but we knew this is what we needed to do, it left us only one answer.

We also had to invert the output cables going to the car’s ECU.

And this is how we fixed the back fires and the rev limit.

We needed to invert the VR crank sensor signal wires and we needed to invert the crank signal output going to the engine ECU.

If you are having a problem with a low RPM rev limit which is also accompanied by backfires and general super rough running but the engine starts/idles, invert the crank sensor signal wires and (if you are using a piggyback ECU) the signals going to the stock ECU. At least that is what worked from us.